Related products

live a message

Weather resistant steels are high strength, low carbon structural steels including small amounts of alloying elements such as copper, chromium, nickel and phosphorus. As a result of these alloying elements and effects of oxygen and humidity, a protective oxide layer is formed on the surface of the steel. The oxide layer prevents the steel from corroding beneath the surface. The thick oxide layer regenerates itself in case of surface damage. The patinated brown-orange appearance of weather resistant steel is formed when the steel is exposed to various weather conditions like humidity and drought. It takes approximately 18-36 months until the protective layer is formed under normal weather conditions. Weather resistant steels are cold formable and great to weld.

Weather resistant steel is commonly known as CORTEN (CORrosion resistance – TENsile strength).

Corten A: steel includes more phosphorus and is most commonly used in architectural structures

Corten B: more suitable for applications requiring high strength due to better impact test results at low temperatures

The products made of weather resistant steel have a long lifespan in even the most challenging weather conditions. Especially architects have found multiple ways to use weather resistant steel when – alongside the structures and costs – the aesthetics of the buildings need to be taken into consideration. The utilization of weather resistant steel reduces the need and thus the costs related to surface treatment. Also thet environmental load is reduced due to its long lifespan.

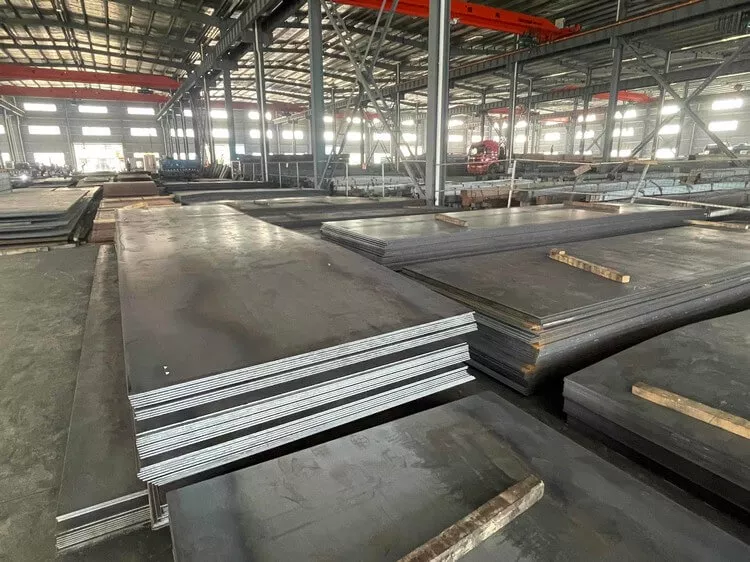

Product Name | hot rolled wear steel ar400 ar500 nm400 nm500 wearing resistant steel plate | ||

Standard | AISI,ASTM, EN, BS, GB, DIN, JIS | ||

| NM360,NM360L,NM400,NM400L,NM400A,NM450,NM450L,NM450A,NM500A.NM550,NM600.NR360,NR400,MITTA 400F,MITTA 450F,MITTA 500F | ||

Inspection | ISO,BV,SGS,MTC | ||

Packing | Waterproof paper, and steel strip packed. | ||

Supply Ability | 250000 metric tons/Year | ||

MOQ | 5 metric ton,sample order accepted | ||

Shipment time | Within 7-10 workdays after receiving deposit or L/C | ||

Payments | T/T,LC | ||

Chemical Content | ||||||||

Steel/Grade | C | Si | Mn | P | S | AL | Cr+Ni+Mo | Nb+V+Ti |

NM360/AR360 | 0.10-0.30 | 0.20-0.40 | 1.00-2.00 | ≤0.015 | ≤0.003 | ≥0.20 | <0.6 |

|

NM400/AR400 | 0.10-0.40 | 0.20-0.40 | 1.00-2.00 | ≤0.015 | ≤0.003 | ≥0.20 | <0.9 | |

NM450/AR450 | 0.10-0.40 | 0.20-0.40 | 1.00-2.00 | ≤0.015 | ≤0.003 | ≥0.20 | <1.2 | |

NM500/AR500 | 0.10-0.40 | 0.20-0.45 | 1.00-2.00 | ≤0.015 | ≤0.003 | ≥0.20 | <1.5 | |

NM550/AR550 | 0.10-0.50 | 0.20-0.45 | 1.00-1.50 | ≤0.015 | ≤0.003 | ≥0.20 | <2.0 | |

NM600/AR600 | 0.10-0.50 | 0.20-0.45 | 1.00-1.50 | ≤0.015 | ≤0.003 | ≥0.20 | <2.5 | |

Mechanical property | ||||

| Tensile strength | Elongation | Hardness | -20ºC Impact energy |

(Mpa) | (%)(min) | (HBW) | AKv/J (min) | |

NM360 | ≥1100 | 12 | 330-390 | 24 |

NM400 | ≥1200 | 10 | 370-430 | 24 |

NM450 | ≥1250 | 7 | 420-480 | 24 |

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

WeChat

WeChat