Related products

live a message

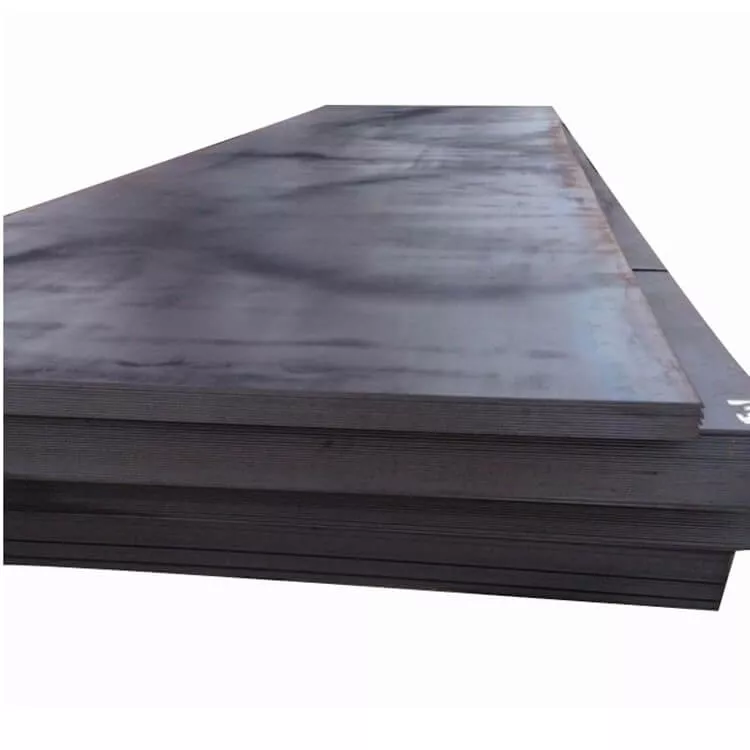

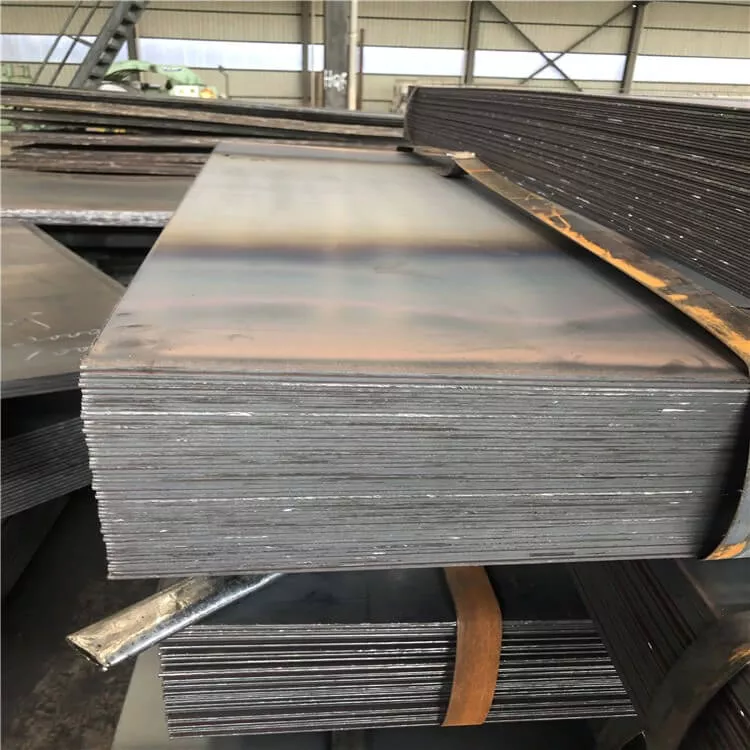

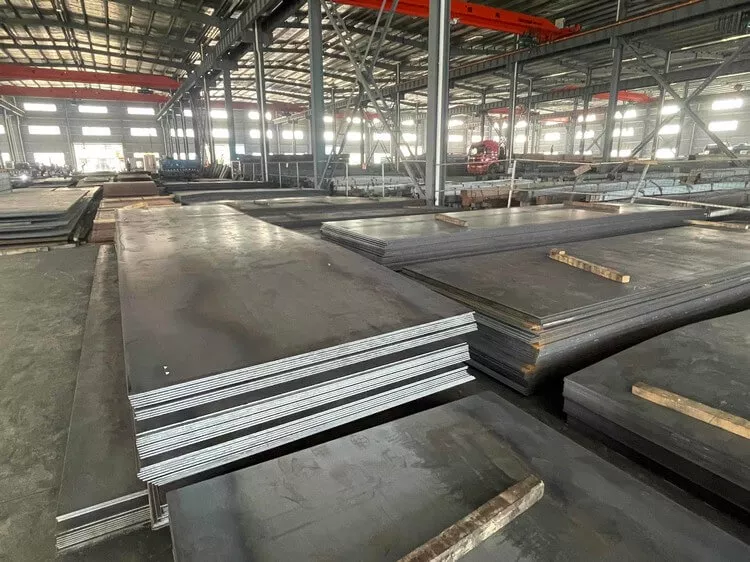

Q235NH atmospheric corrosion resistance steel plate is widely used in containers, chimney, railway engineering and other outdoor steel such as a large outdoor sculpture steel, Lasers produce a high intensity light source the size of a pin head. Q235NH atmospheric corrosion resistance steel plate also is known as hot strip rolling Cowden steel, corrosion-resistant steel.

The energy produced by this light source vaporizes metal. Controlled by CNC (Computerized Numerical Controls) this very narrow beam of high energy light can be directed and its movement controlled with pin point accuracy.

Steel Grade | NM360, NM400, NM450, NM500, NM550, NM600,XAR400,AR450 AR500 ,ect |

Standard | GB, ASTM, JIS ,DIN, ASTM |

Thickness | 2mm-300mm |

Width | 500-2500mm |

Length | 1000mm-12000mm or according to customer's special request |

Tolerance | Thickness: +/-0.02mm, Width:+/-2mm |

1MOQ | 1Tons |

| 1.Automobile, Bridges, Buildings. |

Package | Bundle with steel strip,Container shipping |

Capacity | 200000 tons /month |

Mill MTC | can be supplied before shipment |

Inspection | The Third Party inspection can be accepted,SGS,BV |

| Grade | C | Si | Mn | P | S | Cu | Cr | Ni |

| Q235NH | ≤0.13' | 0.10-0.40 | 0.20-0.60 | 0.03 | ≤0.030 | 0.25-0.55 | 0.4-0.8 | ≤0.65 |

| Grade | Yield strength | Tensile strength | Elongation min % |

GB/T 4171 Q235NH | 215-235 Mpa | 360-510 Mpa | 23 |

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

WeChat

WeChat